The difference is in the details. At WinTech Racing, we realise materials are not all the same which is why we have developed deep relationships with industry leading suppliers and use these in the construction of our boats.

We go a stage further and weave these materials in our state of the art manufacturing facility to achieve custom laminates which meet our exact specifications and testing criteria.

All this results in custom lightweight materials with superior durability, impact resistance as well as torsional and longitudinal stiffness to other leading brands and the ultimate boat for you our customers.

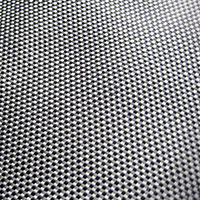

A cloth made up of parallel-oriented carbon fibers held together with some type of binding agent (e.g. epoxy) so it doesn’t fray. “Uni” is ideal when strength is primarily needed in one direction more than any other. Multi directional stiffness is achieved by layering engineered reinforcements in the direction and place needed, thus reducing the total fiber usage where it is not needed and thus, unnecessary weight. “Uni” also uses 10% less resin than a traditional woven cloth, increasing the fiber to weight ration and reducing unneeded resin, allowing more freedom to add reinforcements in other locations.

Carbon comes in various grades of performance, some being “High Modulus” and others being “Standard” or “Low”. High modulus fibers are very stiff and light, but also more costly. High modulus fibres are nearly double the stiffness of standard at 54 million pounds per square inch, compared to 33 million pounds of standard modulus. In our elite boats, we use High Modulus Carbon to maximise the weight to stiffness ratio and provide with a boat that will turn your power into speed. Know why the WinTech Cobra and Medalist are the best boats on the market!

Tkanina składająca się z włókien węglowych ( jak w przypadku przędzy). Włókna składają się z wiązek tysięcy kryształów atomów węgla ułożonych równolegle ( jak nić). Włókno węglowe jest najbardziej znane z wysokiego stosunku wytrzymałości do objętości i wyjątkowej sztywności, ale jest droższe i bardziej kruche niż inne opcje.

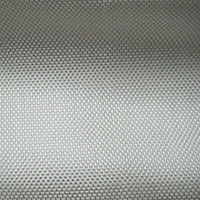

Tworzywo sztuczne wzmocnione włóknem szklanym tkane w arkusz. Włókno szklane jest lekkim i wytrzymałym materiałem, którego koszt jest o wiele niższy niż koszt włókna węglowego lub Kevlaru.®, it is not nearly as strong or stiff.

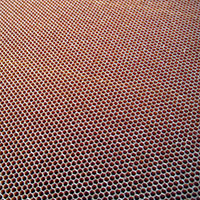

Arkusz komórek o strukturze plastra miodu wykonany z zastrzeżonego włókna syntetycznego firmy DuPont o jakości lotniczej. Struktura komórek pozwala na elastyczność, co czyni go idealnym do stosowania w zakamarkach o małym promieniu, takich jak kadłuby łodzi. Nomex® is used when high strength-to-weight ratios are required.

A proprietary DuPont synthetic fiber that can be woven into fabric. Kevlar® also has very high strength-to-weight volume ratio but is heavier and less stiff than carbon. The upside is that Kevlar® has better fatigue resistance and is less expensive.